In 2021, we expanded our material offerings to service all markets concentrating on sustainability.

About Concordia Engineered Fibers

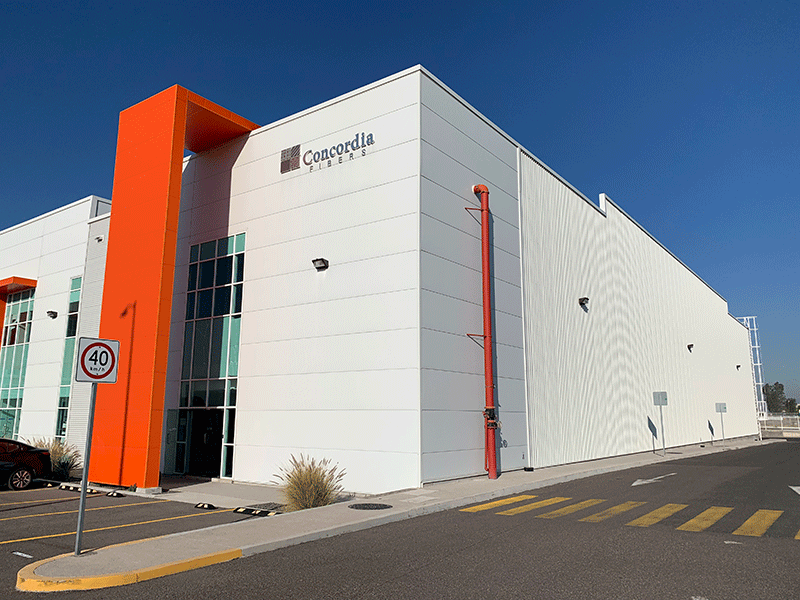

Concordia Today

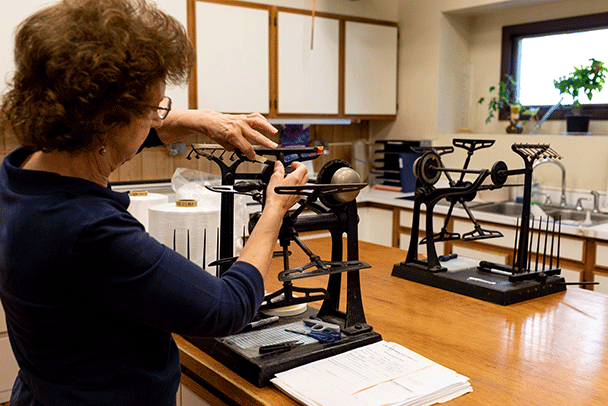

Concordia Engineered Fibers designs and manufactures high-performance, lightweight fibers and composite materials in its Coventry, RI facility for leading apparel, industrial fabric, and advanced composite companies throughout the United States and the world.

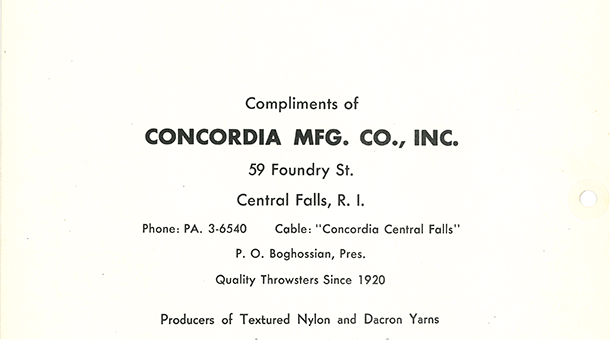

Our Company History

Our Mission

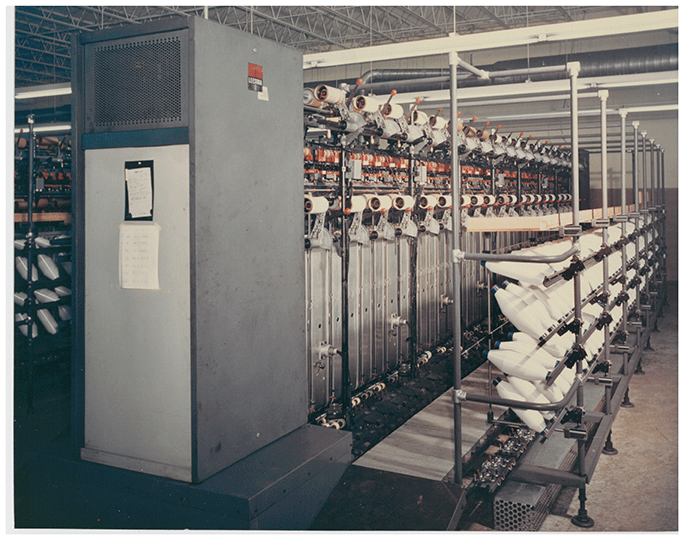

Since 1920, Concordia has specialized in the design and development of engineered yarns and fibers for producing a broad range of technical fabrics. Our fibers can be found in filtration media, power transmission belts, airbags, composite materials, and a variety of other unique applications.

Quality Policy

Concordia consistently provides high-quality products that:

-

Meet or exceed customer requirements

-

Meet applicable regulatory requirements

-

Provide a suitable return to the business

This is achieved through continual review and improvement of our manufacturing methods and the quality management system.